Features & Specs

- BendPak’s proven legacy gives you an edge in performance, service and cost of ownership.

- Designed to be fastened to the floor or free-standing.

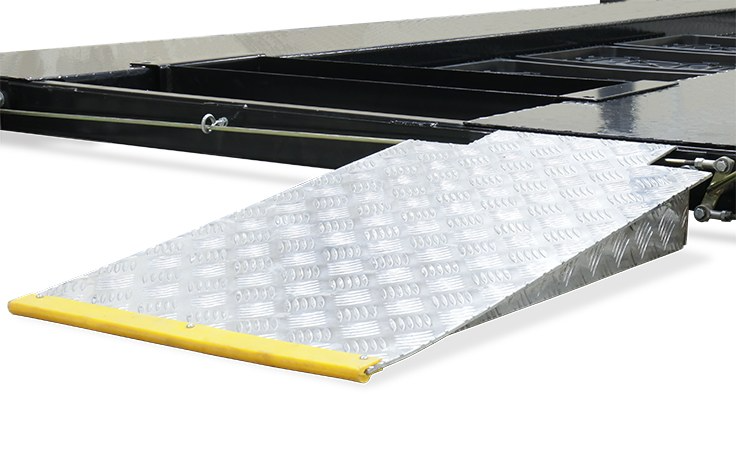

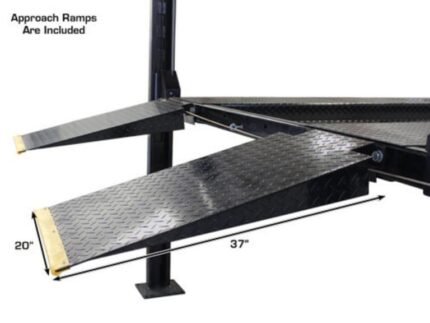

- Comes standard with caster kit, drip trays, mobile jack tray, aluminum approach ramps, and hardened steel tire stops.

- Boxed-steel columns are made from structural 4.75” x 4.75″ welded steel tubing.

- Columns feature 12” x 12” baseplates 5/8” thick.

- Manual dead bolt locks are reliable and safe and are machined directly into the boxed-steel columns.

- 3/4″ thick steel safety locks are spring loaded for automatic and solid engagement.

- 13 positive locking positions are spaced every 4 inches.

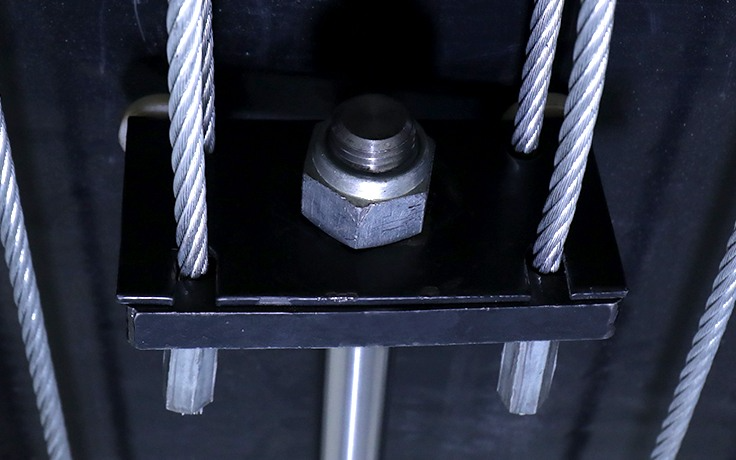

- Secondary slack-cable lock system assures instant back-up safety lock engagement in the event of a cable failure.

- Exterior steel sleeves with UHMV slides surround each column to ensure positive contact and containment.

- ¾” thick safety locks are securely trapped by the full-perimeter cross tube sleeves and can’t become dislodged or disengaged.

- Welded-steel runways feature utility rail for jack tray and drip trays and other accessories.

- Runways are welded and boxed for extra strength.

- Built-in flow restriction integrated into the hydraulic cylinder to prevent free-fall.

- Oversize baseplates and pull-perimeter cross tube sleeves reduce lateral movement and sway when lift is free-standing.

- Low-profile runways are only 5″ high to accommodate low ride-height vehicles.

- Hardened steel safety lock linkages use 3/8” molded carbon steel rod ends to reduce flex and twist to ensure positive locking and smooth operation.

- Precision, reinforced rod ends with spherical bearings are protective coated for corrosion resistance and are designed to provide low friction and high wear resistance.

- 5/8″ thick top caps.

- Sheave axles feature hardened steel collars and snap rings.

- Pull out tire stops on both ends of the lift that allows drive through capability.

- Stainless steel lifting cables are rated to handle over 14,000 lbs. each.

- Cable keepers assures cables remain safely secure to the sheaves.

- Pre-assembled cables simplifies installation.

- 36″ aluminum approach ramps are gusseted to eliminate flex and bending.

- Non-marring heavy-duty poly caster wheels will not damages painted floor surfaces.

- Durable powder coat finish.

- 3/4″ runway bolts provide positive attachment with increased safety factor.

- Operator controls are simple to use, well-placed and ergonomically advanced to reduce operator strain and fatigue and increase safety.

- Electric/hydraulic power system.

- Single hydraulic cylinder underneath runway.

- Optional full-length aluminum platforms can be added to easily store lawnmowers, ATVs, jet skis or motorcycles.

Capacity

Lifting Capacity*

9 000 lbs. (4 082 kg)

*Max Capacity / Front Axle

4 500 lbs. (2 041 kg)

*Max Capacity / Rear Axle

4 500 lbs. (2 041 kg)

Rise

A – Min. Runway Height:

5″ (127 mm)

B – Max. Rise:

70″ (1 778 mm)

C – Max. Lifting Height:

75″ (1 905 mm)

Time to Full Rise:

45 seconds

Outside Dimensions

D – Overall Width:

114,5″ (2 908 mm)

E – Outside Length:

176,5″ (4 483 mm)

F – Overall Length:

203″ (5 156 mm)

G – Height of Columns:

89″ (2 261 mm)

Inside Dimensions

H – Width Between Columns:

98″ (2 489 mm)

I – Drive-Thru Clearance:

86″ (2 184 mm)

Runways

J – Runway Width:

18,75″ (476 mm)

K – Length of Runways:

165,5″ (4 204 mm)

L – Width Between Runways:

37,5″ (953 mm)

M – Runway Centerline:

53,75″ (1 365 mm)

N – Outside Edge of Runways:

72,5″ (1 842 mm)

Minimum Wheelbase

Rated Capacity:

115″ (2 921 mm)

75% Capacity:

100″ (2 540 mm)

50% Capacity:

85″ (2 159 mm)

25% Capacity:

70″ (1 778 mm)

Locking

Locking Positions:

13

Lock Spacing:

Every 4” (102 mm)

Power Unit

Motor:

STANDARD: 110VAC, 50-60HZ, 1PH, 20A or OPTIONAL: 208-230VAC, 50-60HZ, 1PH, 25A

Noise:

45 dB

Shipping

Weight:

2,224 lbs. (1008.8 kg)

Dimensions:

166” x 22” x 43” (4,203 mm x 4,203 mm x 1,092 mm)

Reviews

There are no reviews yet.